Main Menu

- Home

- Products

- Applications

- Product Support

- Service

- Learn

- Product News

- About Us

- Contact Us

A piece of equipment that is designated as intrinsically safe has been designed to operate in a potentially explosive environment. In simplest terms, under any operating conditions, the equipment and wiring are not capable of releasing sufficient electrical or thermal energy for ignition.

What types of environments are potentially explosive? We often think of flammable gasses or fuels, but dust and fine powder can also create potentially explosive environments. Common work environments for which intrinsically safe devices are necessary include on oil rigs, in refineries, in mining operations, pharmaceutical manufacturing, and chemical factories.

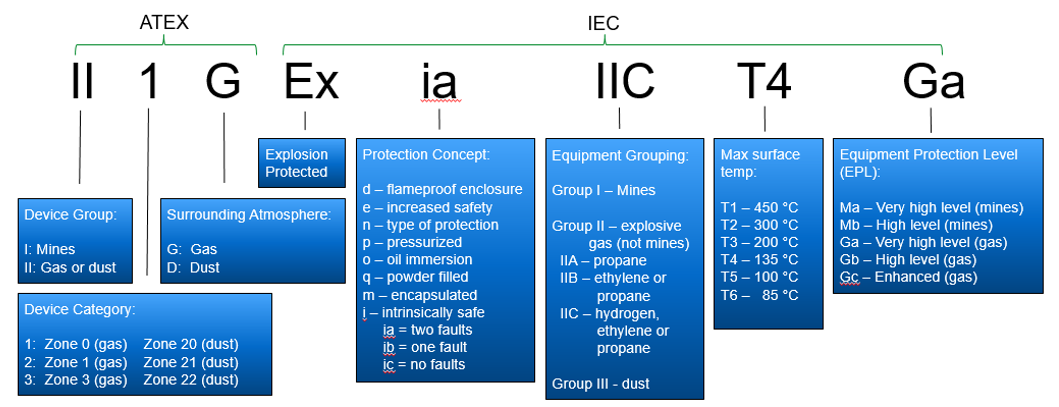

Different areas of the world have different requirements and approvals needed for intrinsically safe products. Be sure to review the specific marking on your equipment to ensure it is suitable for your application.

As a user of intrinsically safe equipment, it is your responsibility to be familiar with the intrinsic safety marking, refrain from tampering with or attempting to repair the device, and use the device as directed. In turn, manufacturers must manufacture and repair the device in the manner approved by the certification agency, provide instructions on proper use, properly mark equipment, and clearly represent the equipment's capabilities

For example, when using Larson Davis' Spartan Intrinsically Safe Noise Dosimeter Model 730IS, only the approved item (the dosimeter itself with clips and windscreen) may be used in the hazardous environment. The Acoustic Calibrator CAL150 or CAL1150, carrying case, and wireless charger may not. The Spartan-IS should be charged, set up, and calibrated prior to being taken into the hazardous environment.

In the USA and Canada, Class indicates the "fuel" present in the environment

Div indicates the risk of an explosive atmosphere

Class 1, Div 1 environments require intrinsically safe devices.

In Europe and throughout the rest of the world, Group and Zone designations are used:

Zone indicates the likelihood of an explosive atmosphere:

| ATEX(IEC) | North America | |

|---|---|---|

| Mines | Group I | |

| Gas | Group II | Class 1 |

| Dust | Group III | Class 2 |

| ATEC (IEC) Gas | ATEC (IEC) Dust | North America | |

|---|---|---|---|

| Explosive atmosphere present | Zone 0 | Zone 20 | Division 1 |

| Explosive atmosphere likely | Zone 1 | Zone 21 | |

| Explosive atmosphere not likely | Zone 2 | Zone 22 | Division 2 |